The Apple Watch popularized strap changing due to its seamless strap release mechanism, which is far more complex to manufacture than one might imagine.

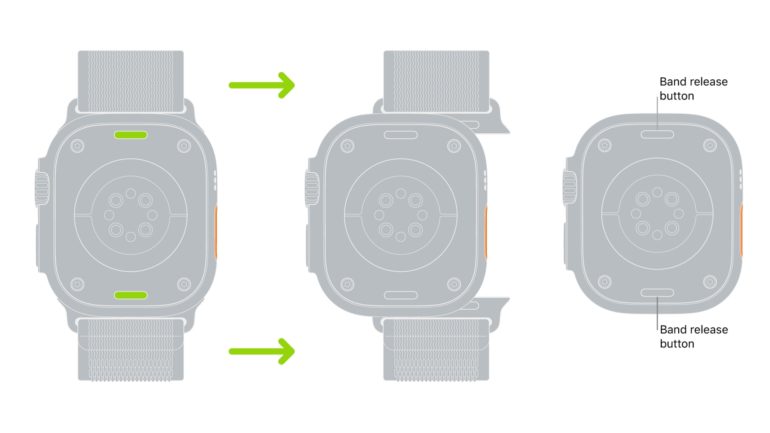

The Apple Watch uses three buttons to connect each band. The interlocking system is so precise that its implementation requires CNC machines cost $2 million each. The proprietary mechanism is virtually foolproof and popularized the exchange of watch straps the Apple Watch because it is easy to use and requires no jeweler’s tools.

A detailed look at the Apple Watch strap release mechanism

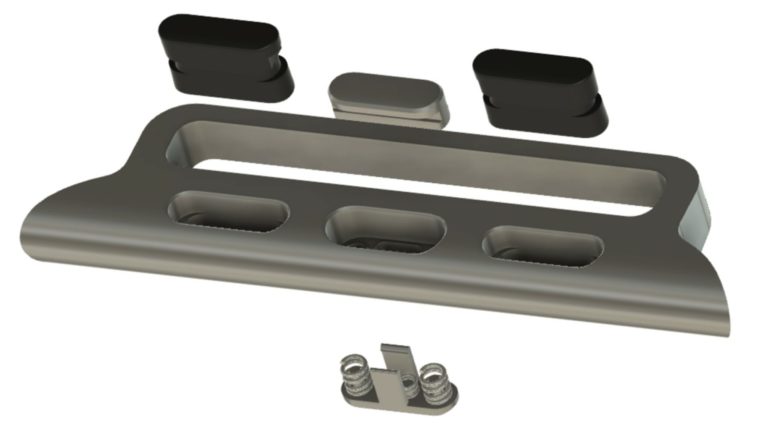

The system is known internally at Apple as the “X206 assembly” and consists of the band part and the watch band system in the band compartment.

The belt part consists of a tooth, a spring mechanism and a pair of rubber shock absorbers. The clock part consists of a gear and spring mechanism, with the springs and pushers responsible for the “click”.

The individual parts are “extremely difficult to machine,” so just to cut the parts for the X206 assembly, Apple had to purchase CNC machines, each costing $2 million.

Tolerances measured in microns

Antonio G. Di Benedetto and Sean Hollister by The edge They spoke to two former Apple engineers who worked on making the parts for the “X206 assembly.”

The band release mechanism has remained the same since the first Apple Watch and is one of the reasons why all Apple Watch bands have remained compatible with different models to this day. Aside from that, user friendliness likely played a major role in launching a $1 billion Apple Watch band ecosystem.

The Cupertino-based company offers a variety of Apple Watch bands made from a variety of materials including silicone, fluoroelastomer, nylon, polyester yarn, leather, stainless steel, and titanium.

insights